| Electrical Communication is a free textbook on the basics of communication technology. See the editorial for more information.... |

|

Home  Fundamentals of Acoustics Fundamentals of Acoustics  Reverberation Reverberation |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

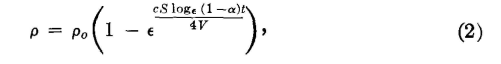

ReverberationIf sound waves are produced in a room or other confined space, they remain audible after the source has ceased emitting until the energy in the waves is dissipated (largely in heat) and the level falls below that required for audibility. This prolonging of sound after the source has ceased emitting is termed reverberation. Both echoes and reverberation are caused by reflected sounds. They differ in that an echo is a "distinct" reflection often of an understandable sound; but reverberation is merely an indistinct "jumble" of reflected sounds. Excessive reverberation is the most common acoustical fault encountered in rooms, studios, and auditoriums. The practicable method of reducing reverberation is to add additional sound-absorbing material to the room. In the past, many attempts have been made to correct the acoustic fault of excessive reverberation by the use of sounding boards and by stringing many feet of overhead wire supposedly to "break up" the sound waves and also to "carry" the sounds back to the rear of the auditorium. Although sounding boards can be used to advantage, there is no known scientific justification for the wires. Of course, what happens in many instances is that a large audience attends on the date of the "grand opening" to observe the effect of the wires, and their clothes absorb the sound, reducing the reverberation to a reasonable value. W. C. Sabine placed architectural acoustics on a scientific basis.7 He determined the sound-absorbing coefficients of a number of materials. Sound from a constant source builds up in a room until a state of equilibrium is reached when the sound is absorbed as rapidly as it is produced. The sound intensity will then become constant unless the energy from the source is changed. When the source is suddenly discontinued, the sound remains audible for a given period, depending on the absorbing power of the room. Sabine, and later Jaeger, developed formulas1,7,8 for the growth and decay of sound in a room. In 1929, Shuster and Waetzmann pointed out that these formulas did not hold for all rooms.9 The equations now generally used are based on the work9 of Eyring. These are, for the growth of sound,

and, for the decay of sound,

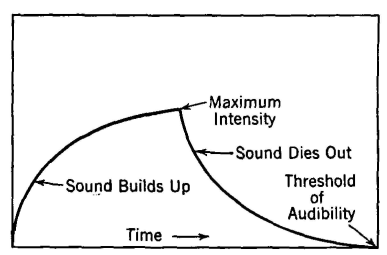

In these expressions, ρ is the sound energy per unit volume in the room at any time t, ρ0 is the sound energy per unit volume when the sound has reached a steady state, c is the velocity of sound in a room, S is the total interior surface of the room, α is the average value of the coefficient of absorption of the entire surface, and V is the volume of the room. The sound energy in a room builds up and dies out according to the logarithmic curve of Fig. 3. Sabine assumed that an open window was a perfect absorber of sound energy and that the absorption coefficient of an open window one foot square was unity, or, as now sometimes stated, one sabine. Other materials and objects used in constructing and furnishing rooms were rated with respect to an open window. In Table I a number of the more common materials are listed. For further information data published by manufacturers should be consulted; also, data will be found in handbooks.5 It should be mentioned that the method of mounting affects the sound-absorbing properties of a material and that sound absorption is not entirely a surface phenomenon. If a material is mounted so that it is free to vibrate, under the influence of sound waves, internal friction between fibers of the material dissipates sound energy and hence affects the absorption coefficient. This fact is often overlooked.10

TABLE I SOUND-ABSORPTION COEFFICIENTS OF TYPICAL MATERIALS AND OBJECTS (From Electrical Engineers' Handbook, Vol. 2, Electric Communication and Electronics, by H. Fender and K. McIlwain.) Thickness Sound-absorption Coefficients in Sabines at Brand or Make Inches Various Frequencies in Cycles

This diaphragm-absorbing action undoubtedly occurs in many materials, even those designed to absorb energy by offering a rough, porous surface to the sound waves. If this were not true, painting unper-forated acoustic material would reduce the absorbing characteristics to substantially those of painted wood. Tests and experience show that it definitely does not do so.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Home  Fundamentals of Acoustics Fundamentals of Acoustics  Reverberation Reverberation |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Last Update: 2011-05-30