| Capacitors, Magnetic Circuits, and Transformers is a free introductory textbook on the physics of capacitors, coils, and transformers. See the editorial for more information.... |

|

Home  Capacitance and Related Effects Capacitance and Related Effects  Dielectric Strength Dielectric Strength |

|||||||||||||||||||||||

|

|||||||||||||||||||||||

Dielectric Strength

The dielectric strength of a material is determined by the maximum electric field intensity it can support without electrical failure. If this value is exceeded the material becomes a conductor. The mechanism of breakdown is discussed in Section 2-25. Values of dielectric strength of some common dielectric materials are listed in Table 2-2.

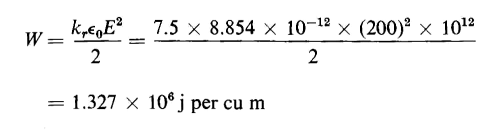

The values of dielectric strength shown in Table 2-2 are not valid for continuous operation, nor are they valid for all configurations of the dielectric. If the materials listed were to be used for storing energy with constant d-c voltage or constant a-c voltage, only much lower values of voltage could be used with safety. To gain some measure of energy capacity, consider mica and its largest value of relative dielectric constant kr = 7.5 and its largest value of dielectric strength 200 X 106 v per m, listed in Table 2-2. The energy that could be stored in a meter cube of mica on that basis would be

or 1.327 j per cu cm, which amounts to 1.327 x 16.387 = 21.7 j per cu in. This value of energy is unrealistically high and it is practically impossible to store this amount of energy in mica. This same amount of energy, however, can be stored magnetically in a cubic inch of air at a flux density of about 117.5 kilolines per sq in., a value that can be realized in practice without great difficulty. The amount of energy that can be stored magnetically in air is limited by the heating of the winding, which furnishes the magnetizing force, and in some cases by magnetic saturation of the iron, which is used to give the air gap its desired configuration.

|

|||||||||||||||||||||||

Home  Capacitance and Related Effects Capacitance and Related Effects  Dielectric Strength Dielectric Strength |

|||||||||||||||||||||||

Last Update: 2011-08-01