| Wireles Networking is a practical guide to planning and building low-cost telecommunications infrastructure. See the editorial for more information.... |

|

Home  Building an Outdoor Node Building an Outdoor Node  Mounting Considerations Mounting Considerations |

|

| See also: Antenna Masts | |

|

|

|

Mounting ConsiderationsIn many cases, equipment can be located inside a building, provided there is a window with ordinary glass through which the beam can travel. Normal glass will introduce little attenuation, but tinted glass will introduce unacceptable attenuation. This greatly simplifies mounting, power, and weatherproofing problems, but is obviously only useful in populated areas. When mounting antennas on towers, it is very important to use a stand off bracket, and not mount the antennas directly to the tower. These brackets help with many functions including antenna separation, antenna alignment and protection. Stand off brackets need to be strong enough to support the weight of the antenna, and also hold it in place on windy days. Remember, antennas can act like small sails, and can put a lot of force on to their mounts in strong winds. When estimating wind resistance, the total surface of the antenna structure must be considered, as well as the distance from the centre of the antenna to the point of attachment to the building. Large antennas such as solid dishes or high gain sectorial panels can have considerable wind load. Using a slotted or mesh parabolic, rather than a solid dish, will help reduce the wind load without much affect on antenna gain. Be sure that the mounting brackets and supporting structure are solid, or your antennas will become misaligned over time (or worse, fall off the tower entirely!) Mounting brackets must have enough clearance from the tower to allow for aiming, but not too much clearance that the antennas become too hard to reach if any service or maintenance is required.

As the equipment will be outside for all of its service life, it is important to be sure that the steel used is weatherproofed. Stainless steel often has too high a price tag for tower installations. Hot galvanizing is preferred, but may not be available in some areas. Painting all steel with a good rust paint will also work. If paint is chosen, it will be important to plan a yearly inspection of the mount and repaint when necessary. Guyed towersA climbable guyed tower is an excellent choice for many installations, but for very tall structures a self supporting tower might be required. When installing guyed towers, a pulley attached to the top of a pole will facilitate the tower installation. The pole will be secured to the lower section already in place, while the two tower sections are attached with an articulated joint. A rope passing through the pulley will facilitate the raising of the next section. After the cantilever section becomes vertical, bolt it to the lower section of the pole. The pole (called a gin pole in the trade) can then be removed, and the operation may be repeated, if required. Tighten the guy wires carefully, ensuring that you use the same tension at all suitable anchoring points. Chose the points so that the angles, as seen from the center of the tower, are as evenly spaced as possible.

Self-supporting towersSelf supporting towers are expensive but sometimes needed, particularly when greater elevation is a requirement. This can be as simple as a heavy pole sunk into a concrete piling, or as complicated as a professional radio tower.

An existing tower can sometimes be used for subscribers, although AM transmitting station antennas should be avoided because the whole structure is active. FM station antennas are acceptable, provided that at least a few of meters of separation is kept between the antennas. Be aware that while adjacent transmitting antennas may not interfere with your wireless connection, high powered FM may interfere with your wired Ethernet cable. Whenever using a heavily populated antenna tower, be very scrupulous about proper grounding and consider using shielded cable.

Rooftop assembliesNon-penetrating roof mount antenna assemblies can be used on flat roofs. These consist of a tripod mounted to a metal or wooden base. The base is then weighed down with bricks, sandbags, water jugs, or just about anything heavy. Using such a rooftop “sled” eliminates the need to pierce the roof with mounting bolts, avoiding potential leaks.

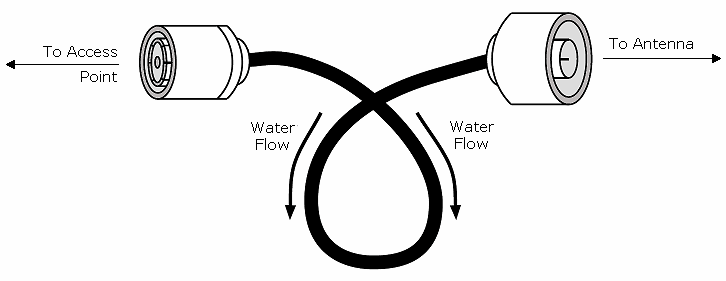

Dissimilar metalsTo minimize electrolytic corrosion when two different metals are in moist contact, their electrolytic potential should be as close as possible. Use dielectric grease on the connection between two metals of different type to prevent any electrolysis effect. Copper should never touch galvanized material directly without proper joint protection. Water shedding from the copper contains ions that will wash away the galvanized (zinc) tower covering. Stainless steel can be used as a buffer material, but you should be aware that stainless steel is not a very good conductor. If it is used as a buffer between copper and galvanized metals, the surface area of the contact should be large and the stainless steel should be thin. Joint compound should also be used to cover the connection so water can not bridge between the dissimilar metals. Protecting microwave connectorsMoisture leakage in connectors is likely the most observed cause of radio link failure. Be sure to tighten connectors firmly, but never use a wrench or other tool to do so. Remember that metals expand and contract as temperature changes, and an over-tightened connector can break in extreme weather changes.

|

|

Home  Building an Outdoor Node Building an Outdoor Node  Mounting Considerations Mounting Considerations |

|

Last Update: 2007-01-24