| Wireles Networking is a practical guide to planning and building low-cost telecommunications infrastructure. See the editorial for more information.... |

|

Home  Building an Outdoor Node Building an Outdoor Node  Solar and Wind Power Solar and Wind Power  Designing a Battery Buffered System Designing a Battery Buffered System |

|||

| See also: Discharging Characteristics | |||

|

|||

|

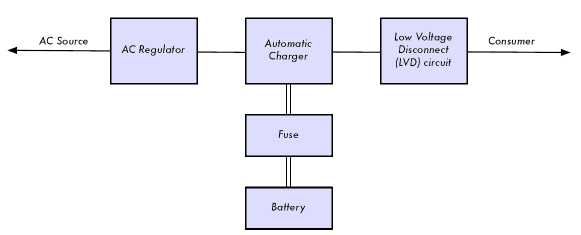

Designing a Battery Buffered SystemThings are less complicated if there is an unstable mains grid available that does its job every now and then. In that case, all that is needed is a decent automatic charger that is capable of fully charging a battery of sufficient size. A switched mode charger with a wide range voltage input and sophisticated charging characteristics is desirable. This will help protect against the grid, which may provide varying voltages. Cheap chargers that feature a simple transformer may never charge your battery at all if the voltage of the grid is too low. A simple charger designed for 230 Volts AC will provide little to no charging current when operated at 200 Volts or lower. No matter how long it operates, it will never achieve a full charge. On the other hand, it will burn out if the voltage is a little higher than expected -or it will simply ruin the batteries after a while. An AC voltage stabilizer that prevents your charger from burning out due excessive high voltage may be a really good idea in many situations. A battery buffered system looks like this: Suppose our device draws 7 Watts at 12 Volts. We need the service 24 hours a day -so the device will draw:

At 12 Volt the current in ampere would be: Now, lets assume that occasionally we get a situation where the grid fails for one week. 1176 Wh = 98 Ah * 12 Volt If we allow our battery to get discharged from 100% to 30% charge, thus consuming 70% of the capacity, we need a storage capacity of: A truck battery is available with this size. Usually power comes back for 5 hours a day, thus the system will run 19 hours on battery. Charging and discharging a battery is never 100% efficient. There will always be energy loss in the battery, so we have to charge with more energy than we get. Charging/discharging efficiency usually is about 75%. We want to charge aggressively and achieve a full charge within 5 hours. Considering charging efficiency: Converting to Ah: Considering charging time: While we are charging the access point/router still draws power. 7 Watts equals 0.6 Ampere at 12 Volts: We should consider that the charging process slows down near the end of the charge period. It would be better to have a higher initial charging current than calculated to achieve a 100% charge. A charging time of 5 hours is quite short, so a IUIa-charger with 8 Amperes or more is a good investment. Even a cheap truck battery should last for 5 years, given that the electrolyte is checked frequently. Don't forget to use a low voltage disconnect circuit. It is not a mistake to oversize such a system to some degree. No matter how well designed the system is, the battery component will wear out and need replacement. In general, it is more cost effective to oversize the power source rather than batteries.

|

|||

Home  Building an Outdoor Node Building an Outdoor Node  Solar and Wind Power Solar and Wind Power  Designing a Battery Buffered System Designing a Battery Buffered System |

|||

Last Update: 2007-01-25